Ball screws efficiently and accurately convert the rotary motion into linear motion and are very important in industries that require precise linear motion. Among the different types of ball screws present, Ball Screw BNT is most preferred because of its precision, durability, and performance in different applications. Whether in manufacturing machinery, robots, or automation systems, Ball Screw BNT provides an ideal solution for high-performance motion control.

What is a Ball Screw?

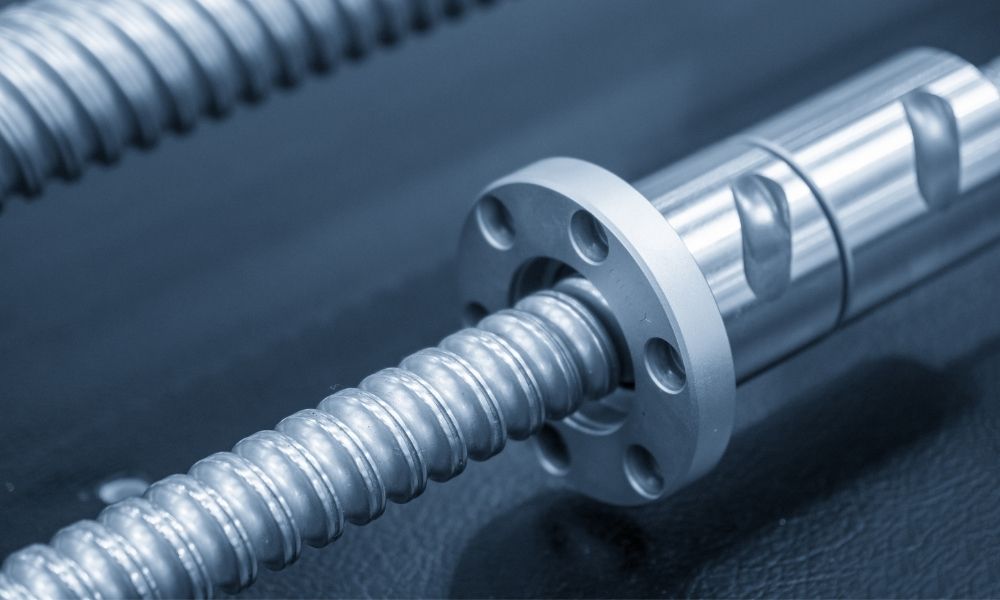

Before explanation on the specifics of Ball Screw BNT (บอลสกรู bnt, which is the term in Thai) one must know what is a ball screw meaning-it is a mechanical linear actuator that translates rotary motion into linear motion with the help of ball bearings. How this system operates is that nut contains steel balls which circulate along a helical groove in the screw shaft. When turning the shaft, the balls recirculate, which reduces friction and permits a smooth, high-precision movement.

High efficiency, precision, and load-carrying capacities define ball-travel screws. On account of accuracy and smoothness as prerequisites, ball screws find application in various engineering sectors, such as CNC machines, 3D printers, and industrial robots.

Why Choose Ball Screw BNT?

In ball screw making BNT is an emerging and best brand- BNT ball screws are well performing and used in applications that require high precision and accuracy, as well as high reliability.

Here are several reasons why Ball Screw BNT stands out:

1.High Precision and Accuracy:

BNT Ball Screw has been manufactured to provide movement that is accurate and with minimum backlash. Such a device is exceptionally suited for any application that calls for exact positioning and repeatability, such as CNC machining, medical devices and automation systems.

2.Low Friction High Efficiency:

The ball bearings use between nut and the screw making motion turns smoother and efficient, while considerably reducing friction. This relatively less wear and tear increase the ball screw’s life and at the same time reduces the frequency of maintenance.

3.Durability:

Ball Screw BNT, bearing premium material and advanced manufacturing, is capable of withstanding heavy loads and demands. This durability allows operation under high-speed and high-load conditions.

4.Quiet in Operation:

The quiet operation of the Ball Screw BNT makes it suitable for environments where noise consideration is paramount, such as in laboratory settings or in applications that require low-noise and smooth motion.

5.Versatile:

Ball Screw BNT finds its applications in various industries, ranging from automotive and aerospace to robotics and medical equipment. Due to this versatility, it adapts to several machine configurations and load requirements suitable for varied applications.

Conclusion

The Ball Screw BNT is an accurate and dependable performance, which is very well suited for those industries requiring precision in linear motion. Superior design, highly efficient and excellent durability combined with its silent operation has enabled it to become the preferred choice for many applications from CNC through robotics to medical devices and even aerospace. Providing manufacturers and engineers with the Ball Screw BNT is the most critical decision they could make in having their systems perform in a highest degree of accuracy and reliability leading to productivity enhancements and a long-term positive imp

Related posts

Categories

- Advertisement (1)

- Business (86)

- Finance (12)

- Franchise (7)

- Marketing (6)

- Networking (5)

- Tech (6)

- Workspace (5)